All DuraGal® products provide a superior level of corrosion resistance through the unique chemical composition of the zinc coating, which also contains 3% Magnesium and 2.5% Aluminium.

This advanced galvanised coating allows consistent and uniform quality during manufacture, can be produced in high volume at any length and provides an attractive, spangle-free surface finish that removes the need for secondary galvanising operations.

Australian Rollforming Manufacturers supplies DuraGal® Lintels for use in residential construction, non-residential construction and for general applications.

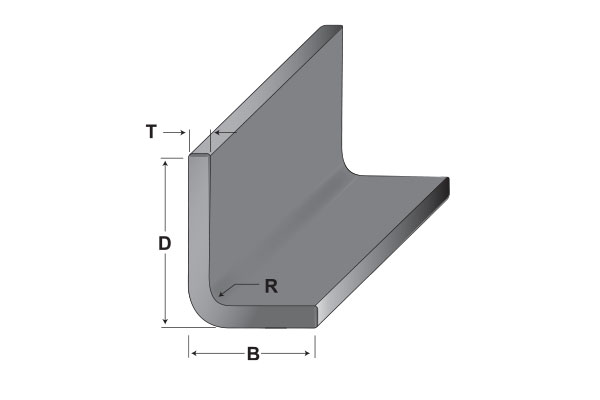

DuraGal® Lintels are readily available in an extensive range of sizes and thicknesses, as shown in the table below:

| DESIGNATION | Pack Size |

Mass (kg/m) |

||

| D | B | T | ||

| (mm) | ||||

| 12.0 Metres | ||||

| 90 | 90 | 5 | 18 | 6.754 |

| 6 | 18 | 8.112 | ||

| 100 | 100 | 6 | 16 | 9.078 |

| 100 | 75 | 6 | 16 | 7.871 |

| 125 | 75 | 6 | 16 | 9.078 |

| 150 | 100 | 6 | 16 | 11.492 |

NEED SOMETHING DIFFERENT?

Australian Rollforming is a custom metal rollforming specialist with the capability to rollform an almost infinite variety of profiles using a wide range of metals.

DuraGal® Lintels can be manufactured to your desired dimensions and lengths with in-line hole punching or edge bevelling also available (nonstandard items may be subject to minimum order quantities). Additional technical specifications, including section properties, are available on request.

Contact us to discuss your requirements.

NOTE: Radius R is a minimum 3.5mm

Attributes of DuraGal®

- Yield strength has a minimum of 350Mpa with a typical range of 350Mpa to 450Mpa.

- Tensile strength has a typical range of 450Mpa to 600Mpa.

- Zinc coating composition has a minimum of 3.0% Magnesium and 2.5% Aluminium.

- Zinc coating has a minimum total mass of both sides of 180g/m2.

- Corrosion Resistance: DuraGal® coating has a minimum composition of 3% magnesium and 2.5% aluminium, demonstrating 5 to 10 times the superior corrosion resistance compared to hot-dip galvanising.

- Self-Healing Protection: The unique DuraGal® coating self heals over exposed and cut edges with a thin zinc–based protective film, hence visible white rust will be less frequent compared to galvanised material which can show 5% white rust within 24h.

- Easily Processed: The chemical composition permits conventional processing operations. DuraGal® is easily used in bending, drawing, clinching, profiling, stamping and welding processes with a stable and lower friction outcome than forming hot-dip galvanised steel.

- Surface Conductivity: Inherently avoids the load of electrical charges, important for applications such as cable trays, PV solar structures or electrical cabinets.

- Hardness & Scratch Resistance: Innate abrasive wear resistance and scratch resistance.

- Improved Surface Quality: The already finished surface removes the need for blasting and priming.

- Reduced Material Management: Eliminates the need to organise secondary galvanising processes.

Please note: The durability performance of DuraGal® is influenced by the micro-environments which vary from site to site. In highly corrosive environments, it is recommended that a suitable barrier coating (e.g. paint or powder coating) be applied in accordance with the supplier’s recommendations with regard to surface pre-treatment, application, curing and maintenance of the coating.

Call Us

Call Us