Australian Rollforming Manufacturers produce an extensive range of standard and custom formed conveyor sections that provide significant economic benefits when compared to conventional hot-rolled profiles.

Made from G450 high tensile steel with either a Z300 or Z450 galvanised coating, Australian Rollforming Manufacturers’ conveyor sections combine high strength with low mass and are highly corrosion resistant.

This combination of high strength and low mass results in significant economies in initial cost, fabrication, transport, handling and erection.

Pre-punched, prefabricated and modular frame assemblies also result in outstanding handling and transport logistics and reduced erection time.

Australian Rollforming Manufacturers’ conveyor sections are precision made to exacting tolerances, and consistency of components ensures ease of assembly and provides significant time and cost savings.

Being highly corrosion resistant also ensures a long lifespan and can eliminate the need for other costly protective treatments.

Dimensions and properties — standard sections

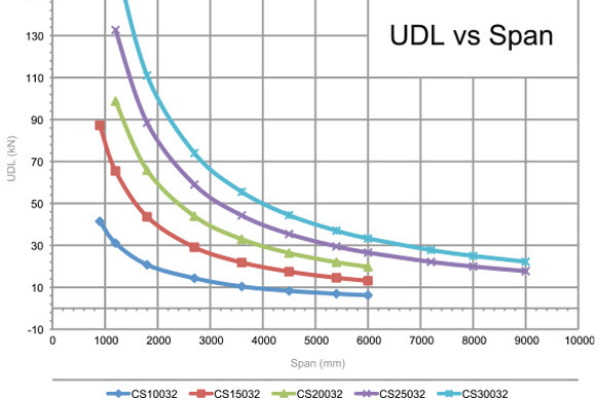

Australian Rollforming Manufacturers’ standard range of conveyor sections consists of two main types – plain or ‘C’ sections, and lipped sections. C sections are denoted by the prefix ‘LC’ and lipped sections are denoted by the prefix ‘CS’. The CS range incorporates a stiffened top flange for rigid mounting of the idlers and a plain bottom flange to minimise retention of moisture and dirt.

| Ref. | Dimensions (mm) |

Area (mm²) |

Mass (kg/m) |

Centroid (mm) |

Second moment of area (10⁶ mm⁴) |

Section modulus (10³ mm³) |

Radius of gyration (mm) |

||||||||

| D | B | T | d | t | Cx | Cy | Ix | Iy | Zx | Zy | Rx | Ry | |||

| LC15030 | 150 | 50 | 50 | n/a | 3.0 | 720 | 5.2 | 75.0 | 11.4 | 2.300 | 0.159 | 30.67 | 4.12 | 75.6 | 19.4 |

| LC20030 | 200 | 65 | 65 | n/a | 3.0 | 960 | 7.4 | 100.0 | 17.1 | 5.489 | 0.360 | 54.89 | 7.52 | 56.6 | 14.9 |

| CS10032 | 100 | 50 | 45 | 24 | 3.2 | 643 | 5.0 | 45.8 | 16.3 | 0.936 | 0.192 | 17.26 | 5.68 | 38.2 | 17.3 |

| CS15032 | 150 | 75 | 55 | 24 | 3.2 | 915 | 7.1 | 66.2 | 20.5 | 3.046 | 0.546 | 36.35 | 10.02 | 57.8 | 24.5 |

| CS20032 | 200 | 75 | 55 | 24 | 3.2 | 1074 | 8.3 | 89.7 | 17.7 | 6.050 | 0.595 | 54.86 | 10.37 | 75.1 | 23.6 |

| CS25032 | 250 | 75 | 55 | 24 | 3.2 | 1235 | 9.6 | 136.5 | 59.4 | 10.432 | 0.637 | 76.43 | 10.72 | 91.9 | 22.7 |

| CS30032 | 300 | 100 | 80 | 24 | 3.2 | 1555 | 12.0 | 161.1 | 78.5 | 19.875 | 1.453 | 123.37 | 18.52 | 113.1 | 30.6 |

Australian Rollforming Manufacturers are custom metal rollforming specialists, with the capability to rollform an almost infinite number of profiles in a wide range of metals.

Contact us to discuss your requirements.

Call Us

Call Us