Australian Rollforming Manufacturers produce an extensive range of standard and custom formed steel sheet piling products to suit a wide variety of applications and conditions.

Common applications for Australian Rollforming Manufacturers’ sheet piling include trenching; water conservation e.g. dams, dam cores, coffer dams; waterways e.g. canal walls, dock walls, bulkheading; erosion control e.g. check dams, beach groynes, cliff protection; structural e.g. excavation and retaining walls, underpinning, formwork, bridge decks and piers, jetties, docks and causeways.

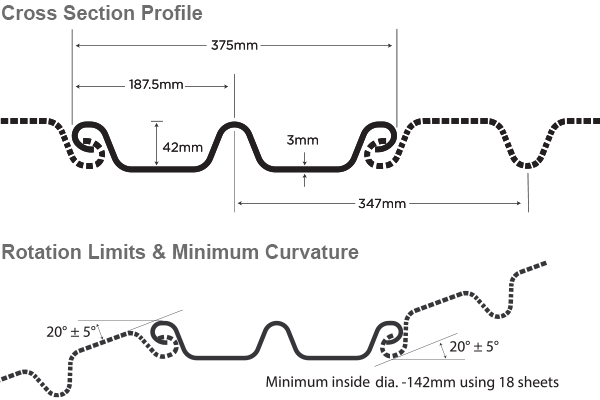

LP042/61 medium-duty piling

Australian Rollforming Manufacturers’ LP042/61 medium-duty steel sheet piling is designed to provide maximum strength, consistent with accurate, easy driving, extraction and handling. It is light and easily handled – approximately 15 kilograms per metre. LP 042/61 requires only light driving hammers, simple rigs and tooling.

LP042/61 sheets are long lasting, whether used for permanent installations or re-used for numerous temporary requirements.

The sheets are cold rollformed for accuracy of profile with straightness. Strict quality control maintains standards of performance and resistance to scouring forces.

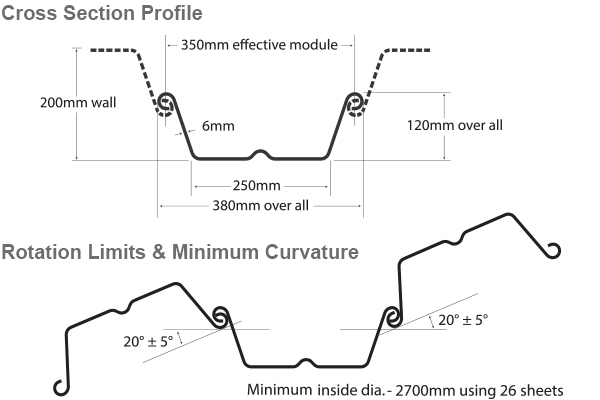

LP200/80 heavy-duty piling

Australian Rollforming Manufacturers’ LP200/80 was developed to meet a need for a medium-duty, multi-purpose section. LP200/80 is lighter, less expensive and easier to handle than heavy sheet piling sections.

In addition, because it has several times the strength of light sections, LP200/80 can be used on a wide variety of projects and under more demanding driving conditions than is possible with lightweight sheet pilings.

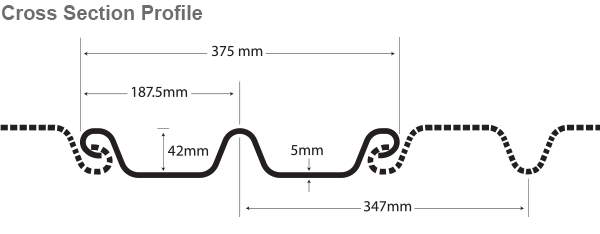

LP042/57 medium-duty wide piling

Australian Rollforming Manufacturers’ LP042/57 steel sheet piling is developed specifically for sandy conditions as a cost-effective means to simplify trenchwork, eliminating the need for bracing.

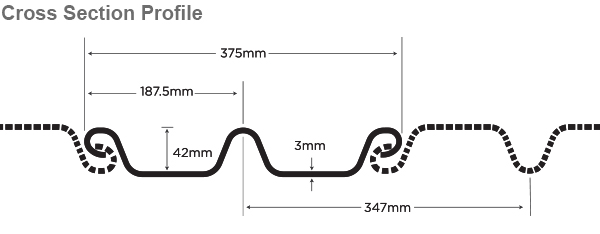

LP042/34 lightweight wide piling

Australian Rollforming Manufacturers’ LP042/34 lightweight wide sheet piling is used primarily for the prevention of soil erosion.

This is achieved by driving a series of check dam walls into position across the path of a water course and backfilling with heavy ballast.

This results in a significant slowing of the water movement and therefore reducing the amount of erosion.

Maximum wall height (H) & minimum piling depth (D) (mm)

| Type of soil or fill | LP042/34 | LP042/57 | LP042/61 | LP200/80 | ||||

| H | D | H | D | H | D | H | D | |

| Well graded sand & gravel | 1880 | 1170 | 2260 | 1410 | 1960 | 1220 | 3730 | 2320 |

| Fine or silty sand | 1810 | 1370 | 2180 | 1650 | 1890 | 1430 | 3600 | 2720 |

| Soft clay | 1630 | 2680 | 1960 | 3230 | 1700 | 2800 | 3240 | 5330 |

| Stiff clay | 1570 | 2590 | 1890 | 3110 | 1640 | 2700 | 3120 | 5140 |

NOTES:

Maximum height of wall (H) and the corresponding minimum driven depth (D) depend on the type of soil and the strength of the sheet piling. Where the fill differs from the soil into which the piling is driven, use the H & D values of the respective soil type.

Section properties

| Code No. | Dimensions | For one section | For metre width of assembled sheets |

|||||||||

| t | H | W | Module | Area A | Mass per unit Length |

Ixx | Zx | Area A | Mass per unit Area |

Ixx | Zx | |

| mm | mm | mm | mm | mm² | kg/m | 106mm4 | 103mm3 | mm² | kg/m² | 106mm4 | 103mm3/m | |

| LP042/34* | 3.0 | 42 | 375 | 347 | 1500 | 11.78 | 0.35 | 12.56 | 4323 | 33.95 | 0.67 | 21.91 |

| LP042/57 | 5.0 | 42 | 375 | 347 | 2500 | 19.63 | 0.51 | 18.6 | 7205 | 56.56 | 1.13 | 36.57 |

| LP042/61 | 5.0 | 42 | 273 | 245 | 1910 | 14.90 | 0.39 | 16.9 | 7800 | 60.9 | 1.87 | 76.30 |

| LP200/80 | 6.0 | 200 | 380 | 350 | 3620 | 28.96 | 6.88 | 95.0 | 10340 | 79.8 | 52.40 | 524.00 |

Piling reference numbers

Reference number components denote properties of a finished wall using that particular section. The first number denotes the overall thickness of the wall and the second its mass per square metre. Thus LP 200/80 gives a wall thickness of 200mm and a mass of 80 kg/m2.

This referencing method enables easy comparison with other sheet piling sections. Australian Rollforming Manufacturers are custom metal rollforming specialists with the capability to rollform an almost infinite number of profiles in a wide range of metals.

Contact us to discuss your requirements.

Call Us

Call Us