DuraGal® Profiles provide a superior level of corrosion resistance compared to hot-dip galvanising through the unique chemical composition of the zinc coating, which contains a minimum of 3% Magnesium and 2.5% Aluminium.

This advanced galvanised coating allows consistent and uniform quality while processing and provides an attractive, spangle free surface finish that removes the need for secondary galvanising operations.

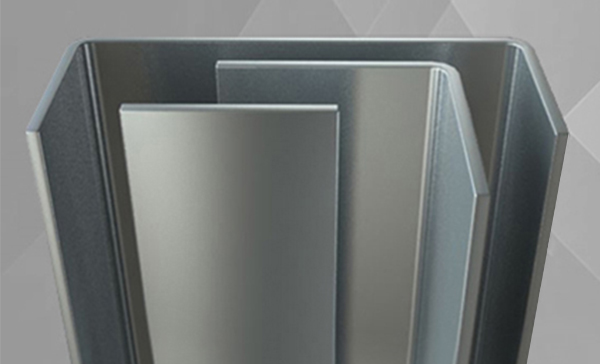

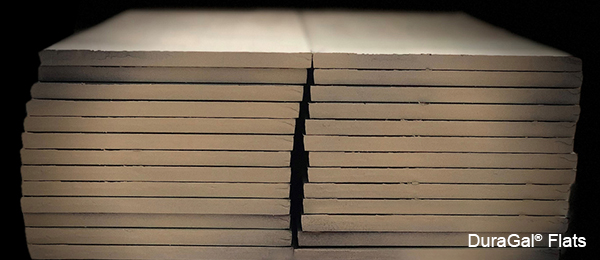

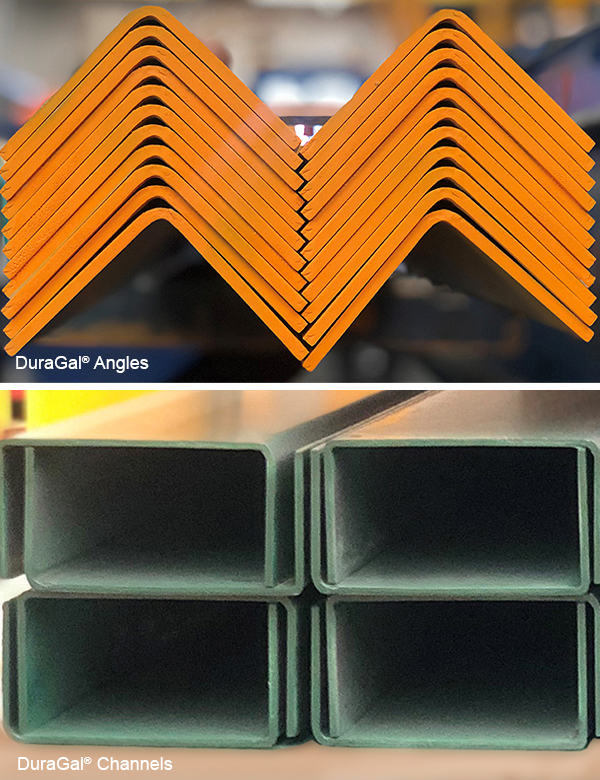

DuraGal® Angles, Channels, Flats and Lintels can be manufactured to your desired dimensions and lengths with in-line hole punching or edge bevelling also available (non-standard items may be subject to minimum order quantities).

Attributes of DuraGal®

- Yield strength has a minimum of 350Mpa with a typical range of 350Mpa to 450Mpa.

- Tensile strength has a typical range of 450Mpa to 600Mpa.

- Zinc coating composition has a minimum of 3.0% Magnesium and 2.5% Aluminium.

- Zinc coating has a minimum total mass of both sides of 180g/m2.

- Corrosion Resistance: DuraGal® coating has a minimum composition of 3% magnesium and 2.5% aluminium, demonstrating 5 to 10 times the superior corrosion resistance compared to hot-dip galvanising.

- Self-Healing Protection: The unique DuraGal® coating self heals over exposed and cut edges with a thin zinc–based protective film, hence visible white rust will be less frequent compared to galvanised material which can show 5% white rust within 24h.

- Easily Processed: The chemical composition permits conventional processing operations. DuraGal® is easily used in bending, drawing, clinching, profiling, stamping and welding processes with a stable and lower friction outcome than forming hot-dip galvanised steel.

- Surface Conductivity: Inherently avoids the load of electrical charges, important for applications such as cable trays, PV solar structures or electrical cabinets.

- Hardness & Scratch Resistance: Innate abrasive wear resistance and scratch resistance.

- Improved Surface Quality: The already finished surface removes the need for blasting and priming.

- Reduced Material Management: Eliminates the need to organise secondary galvanising processes.

Note, additional technical specifications, including section properties, are available upon request. Contact us today.

Please note: The durability performance of DuraGal® is influenced by the micro-environments which vary from site to site. In highly corrosive environments, it is recommended that a suitable barrier coating (e.g. paint or powder coating) be applied in accordance with the supplier’s recommendations with regard to surface pre-treatment, application, curing and maintenance of the coating.

Call Us

Call Us