Australian Rollforming Manufacturers’ trench sheeting has been specially designed for quick and easy installation and extraction in trench work and shoring applications.

The simple lapping method of Australian Rollforming Manufacturers’ trench sheets allows the product to be easily re-used and repaired by use of brake pressing, in the event of damage while driving.

Piling Reference Numbers

Reference number components denote properties of a finished wall using that particular section. The first number denotes the overall thickness of the wall and the second its mass per square metre.

| Code No. | Dimensions | For one section | For metre width of assembled sheets |

|||||||||

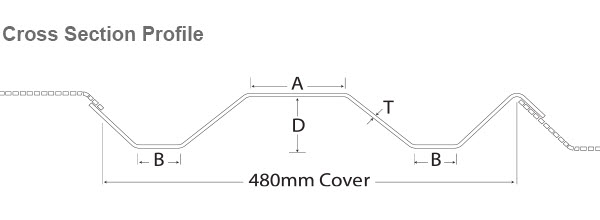

| T | A | B | D | Area A | Mass per unit length |

Ixx | ZxB | Area A | Mass per unit area |

Ixx/m | Zx/m | |

| mm | mm | mm | mm | mm² | kg/m | 10⁶mm⁴ | 10³mm³ | mm² | kg/m² | 10⁶mm⁴ | 10³mm³/m | |

| LTS064/29* | 3 | 111 | 51 | 64 | 1779 | 14.0 | 0.9 | 28.3 | 3706 | 29.1 | 1.9 | 58.8 |

| LTS065/39 | 4 | 112 | 52 | 65 | 2372 | 18.6 | 1.2 | 37.1 | 4942 | 38.8 | 2.6 | 77.2 |

Availability

LTS064/29 and LTS065/39 trench sheets are rollformed from 3mm and 4mm thick hot rolled steel and are available in a range of stock lengths or custom cut to size. Australian Rollforming Manufacturers’ trench sheets can also be produced in other thicknesses to suit specific requirements – please enquire.

Notes

Maximum height of wall (H) and the corresponding minimum driven depth (D) depend on the type of soil and the strength of the sheet piling. Where the fill differs from the soil into which the piling is driven, use the H & D values of the respective soil type.

Australian Rollforming Manufacturers are custom metal rollforming specialists with the capability to rollform an almost infinite number of profiles in a wide range of metals.

Contact us to discuss your requirements.

Call Us

Call Us