Australian Rollforming Manufacturers produced key components for the VLocity passenger trains, as part of the Victorian Government’s Regional Fast Train project.

The components manufactured by Australian Rollforming Manufacturers included cant rails, corrugated roof panels, side sill assemblies, corrugated side walls and underframes.

Rollformed from 304 grade stainless steel in Australian Rollforming Manufacturers’ production facility in Dandenong, Victoria, these components were supplied to Bombardier Transportation, that built the trains.

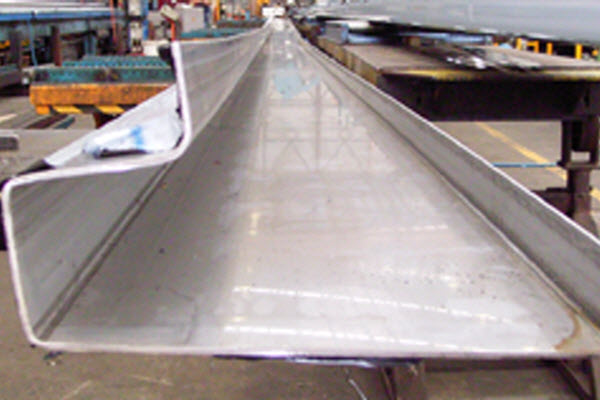

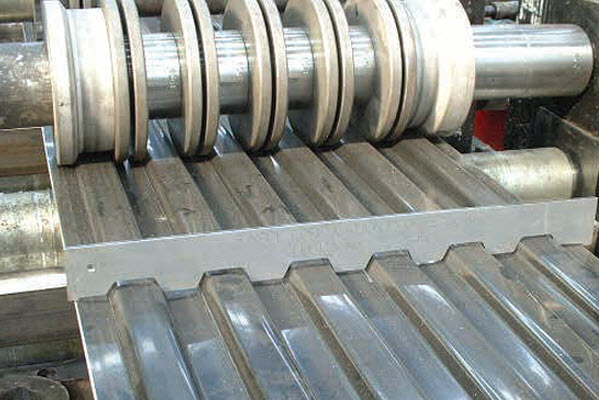

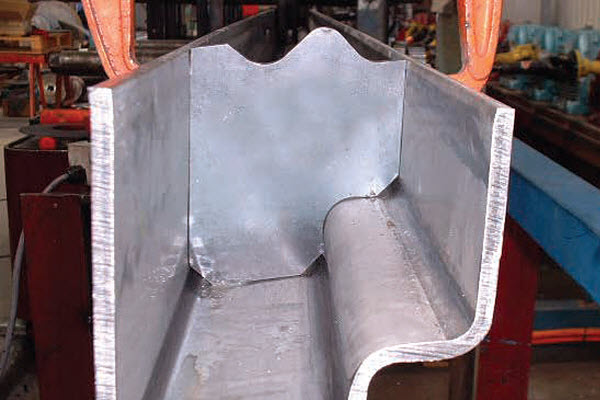

Thicknesses ranged from 1.2mm for the outer wall panels; 2mm for the corrugated roof panels and floor underframe; 4mm for the cant rails; and 6mm for the side sills.

The components were up to 25 metres in length, therefore straightness of the panels and being free of any bowing were critical.

Manufacturing tolerances were very tight, with many being down to ± 0.5mm, and adherence to these tolerances was essential as each component went to a robotic welding process as part of the overall assembly process.

The overall project called for 100 carriages to be built and it was essential that Australian Rollforming Manufacturers were able to deliver finished components to spec, on time and in the required quantities in accordance with Bombardier Transportation’s demanding build schedule.

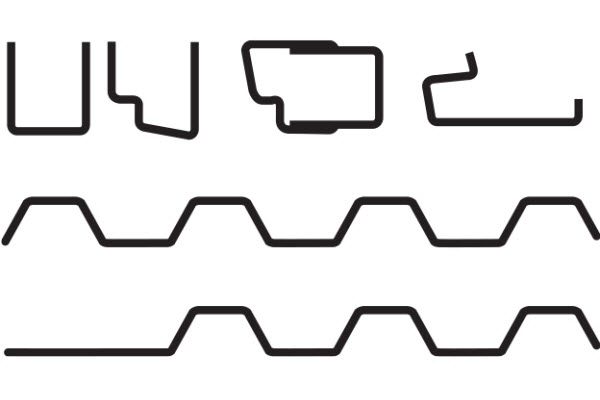

Australian Rollforming Manufacturers produce a number of key components, including cant rails, roof and wall panels, side sill assemblies and underframes, for all types of rail passenger carriages, including light and heavy rail, tram and monorail vehicles.

Cant rails

Roof & wall panels

Side sills

Assembled wall panels

Australian Rollforming Manufacturers are custom metal rollforming specialists, with the capability to rollform an almost infinite number of profiles in a wide range of metals.

Contact us to discuss your requirements.

Call Us

Call Us