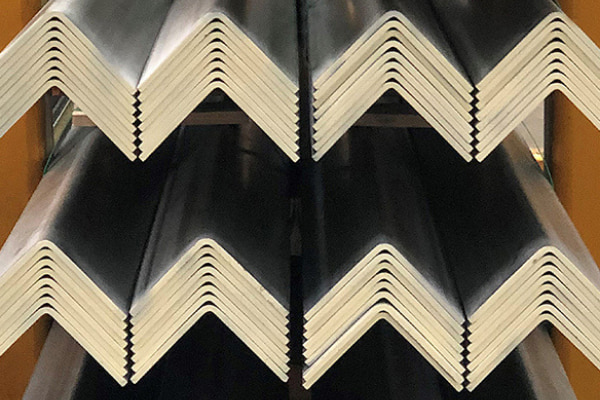

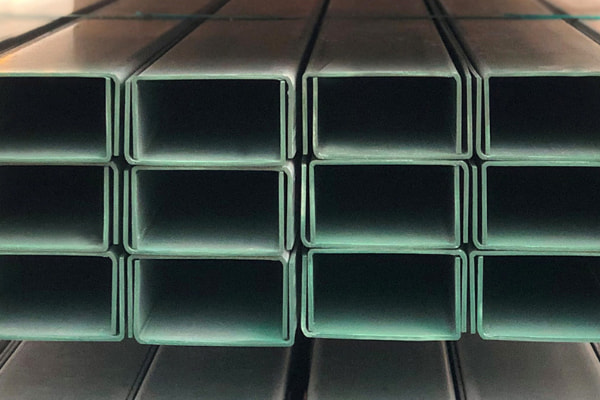

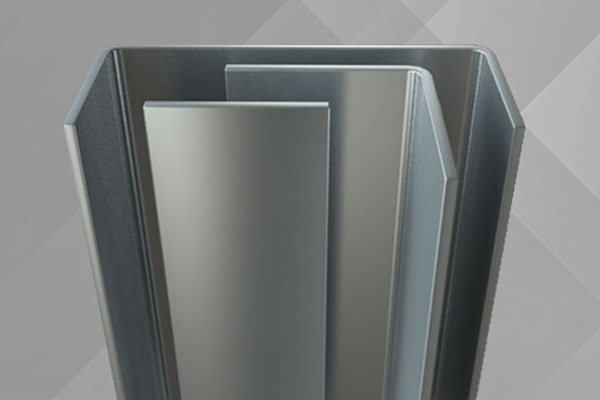

We use DuraGal® at Australian Rollforming Manufacturers because we can have unlimited length, consistency and uniformity of profile, closer and tighter tolerances, high volume, high-speed preparation, can incorporate secondary operations in the one process and it has superior surface finish.

DuraGal® Profiles have a high level of corrosion resistance given the chemical composition of zinc with 3% Magnesium content and 2.5% Aluminium. The Magnesium creates a stable and durable layer across the entire surface and gives a far more effective corrosion protection than coatings with a lower Magnesium content.

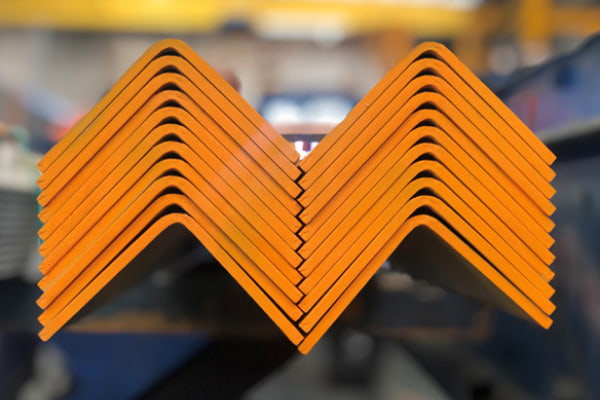

The durability performance of DuraGal® is influenced by the micro-environments which vary from site to site. In highly corrosive environments, it is recommended that a suitable barrier coating, (e.g. paint or powder coating) be applied over the galvanised surface, and that the application of such coating be fully in accordance with the supplier’s recommendations with regard to surface pre-treatment, application, curing and maintenance of the coating.

Call Us

Call Us